Complete Guide to Sublimation Printing: Essentials & Techniques

Posted by ARTEMIO NERVEZ JR

Sublimation printing, a revolutionary technique in the world of digital printing, offers incredible possibilities for creating high-quality, vibrant, and long-lasting designs. This guide aims to provide you with a thorough understanding of sublimation printing, covering its fundamentals, the necessary materials, and the techniques involved.

What is Sublimation Printing?

Sublimation printing is a digital printing method that uses heat to transfer dye onto materials such as fabric, paper, and plastic. This process involves turning a solid dye into a gas without passing through the liquid stage and embedding the ink into the substrate, which results in durable and high-resolution prints.

Key Advantages

- Durability: The ink becomes part of the substrate, leading to fade-resistant and durable prints.

- Quality: It produces vibrant colors and high-resolution images.

- Versatility: Suitable for a range of materials, including textiles and rigid substrates.

Essential Materials

- Sublimation Ink: Specialized ink that turns into gas under heat.

- Sublimation Printer: A printer compatible with sublimation ink.

- Transfer Paper: A paper designed to hold the sublimation ink.

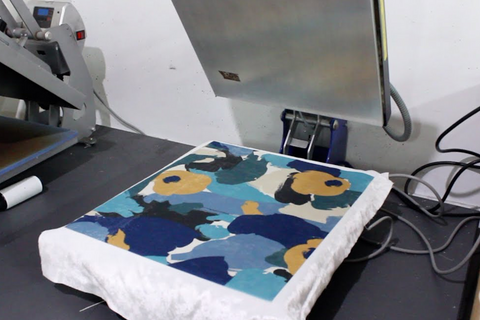

- Heat Press: A machine that applies heat and pressure for the transfer.

- Substrates: Materials like polyester fabrics or coated items.

Step-by-Step Process

- Design Creation: Use graphic software to create or select your design.

- Print the Design: Print it onto the sublimation paper using the sublimation printer.

- Prepare the Substrate: Place the substrate into the heat press.

- Sublimation: Place the printed paper on the substrate and press it under high temperature.

-

Cool Down: Remove the substrate and allow it to cool.

Tips and Tricks

- Material Compatibility: Ensure your substrate is compatible with sublimation printing, preferably made of polyester or coated with a special polymer.

- Temperature and Time: Adhere to the specific temperature and time settings for different materials.

- Testing: Always test on a small area or a sample piece first.

Applications

Sublimation printing is widely used in various industries, including:

- Fashion: Custom apparel, sportswear, and accessories.

- Home Decor: Personalized curtains, cushions, and mats.

- Advertising: Banners, flags, and displays.

- Personalized Products: Mugs, phone cases, and photo panels.

Conclusion

Sublimation printing stands out for its ability to produce vivid, long-lasting prints on a variety of surfaces. While the process requires specific materials and a bit of practice, the resulting products are often of superior quality. Whether you're a hobbyist, a small business owner, or a professional in the printing industry, mastering sublimation printing can open up a world of creative and commercial possibilities.

At VS Tees, we pride ourselves on our expertise in sublimation printing, a method renowned for delivering vibrant and enduring prints across diverse surfaces. This technique, while demanding precise materials and some practice, consistently yields products of exceptional quality. Whether you're an enthusiast exploring a new hobby, running a small business, or a seasoned expert in the printing sector, perfecting the art of sublimation printing can unlock a vast array of creative and business opportunities.