DTG vs. Screen Printing: Which Wins on Quality & Cost?

Posted by ARTEMIO NERVEZ JR

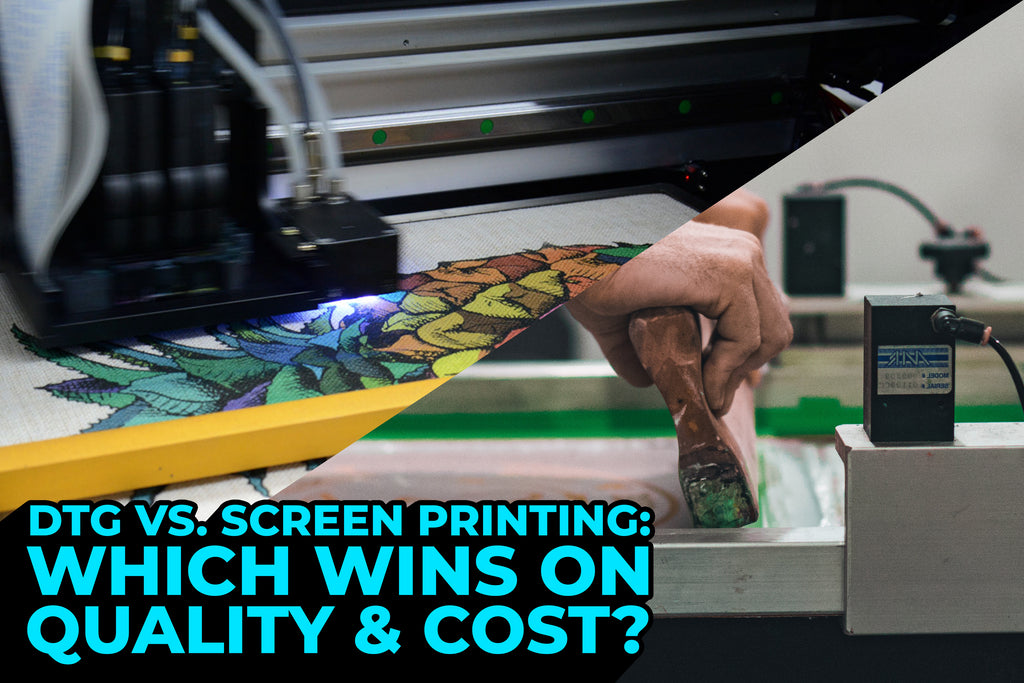

When you're standing at the crossroads of quality and cost in the world of custom apparel printing, the choice between DTG (Direct-to-Garment) and Screen Printing technologies is pivotal. Let's cut to the chase: Screen Printing excels in cost-effectiveness for larger orders, offering vibrant, long-lasting prints, while DTG shines with its detailed imagery and suitability for smaller batches, though at a higher cost per item. Choosing the right path depends on your project's scale, design complexity, and budget.

Delving into the custom printing scene, we uncover two titans: DTG, a relatively new but mighty player harnessing the precision of digital technology to print directly onto the fabric, and Screen Printing, the seasoned veteran known for its iconic stenciling technique. Each method carries its own set of charms and challenges. Screen Printing, with its layers of rich ink, brings designs to life with a boldness that can withstand the test of time and countless washes. On the other hand, DTG, with its nuanced color variations, is akin to a painter meticulously detailing every stroke on a canvas.

As we stitch together the narratives of these two printing powerhouses, we're primed to unravel the threads of DTG's intricate digital artistry in the next section, "The Fundamentals of DTG Printing." Remember, while your choice between the two may hinge on various factors, the ultimate goal remains constant: to don apparel that boasts both flair and finesse, mirroring the quintessential streetwear spirit that V.S. Tees embodies.

The Fundamentals of DTG Printing

What is DTG Printing?

Direct-to-garment (DTG) printing is a relatively new technology that allows for the direct application of textile inks onto garments using inkjet technology. It's akin to printing on paper but instead, your t-shirt becomes the canvas. This method is particularly beneficial for intricate designs with a multitude of colors, providing a high-resolution finish that's tough to beat.

The beauty of DTG lies in its capacity to print just one piece or a small batch without the setup costs associated with traditional screen printing. It's an ideal solution for personalized items or limited edition runs. The inks used are water-based, which soak into the fabric, leaving a soft-to-the-touch feel on the garments. This method is perfect for those demanding a sharp, clean print with a lot of details.

DTG Printing Materials and Inks

When it comes to materials, not all fabrics are equal in the eyes of DTG printing. The process works best on 100% cotton or high-cotton blends, as the natural fibers absorb the ink more effectively. Synthetic materials can also be used but might not yield the same vibrant results.

The inks are a story of their own. DTG printers use special aqueous ink that is formulated to bind with the fibers of the garment. This ensures that the ink doesn't just sit on top of the fabric but becomes part of it. The result is a more durable and long-lasting image. However, the longevity of the print can also depend on how the garment is cared for. Proper washing and drying can extend the life of a DTG-printed shirt significantly.

Cost and Efficiency of DTG Printing

One of the most commonly asked questions is about the cost of DTG printing. While the initial investment for a DTG printer can be significant, the per-unit cost for printing is relatively low, especially for small orders. This makes it a cost-effective solution for custom apparel businesses or designers who want to offer personalized items without the need for a large inventory.

In terms of efficiency, DTG wins hands down for short runs. The process is digital, so it's as simple as pressing print on your computer. There's no need for screens or setup time, which means orders can be fulfilled quickly. This efficiency makes it an attractive option for businesses that need to respond rapidly to market trends or customer requests.

As we consider the artistry and precision that go into creating custom apparel, it's clear that DTG printing plays a pivotal role. With its ability to produce high-quality, cost-effective prints, it suits those who wish to express their creativity without being constrained by the limitations of more traditional printing methods. If you're intrigued by the potential of DTG printing and how it can elevate your designs, our custom printing services at V.S. Tees can help turn your vision into wearable art.

Transitioning from the nuts and bolts of DTG printing, we weave into the broader tapestry of garment customization. The interplay between technology and textiles crafts a narrative where every thread is a possibility, and every color is a story waiting to be told. In this fabric of creativity, the threads of innovation intertwine with the yarns of tradition, leading us to another facet of garment embellishment.

As we embrace the seamless blend of old and new, we witness the time-honored techniques of screen printing converging with modern advancements. This synergy of methods allows for a diverse range of expression, from the bold statements of streetwear to the subtle nuances of vintage-inspired fashion. It's here, in the delicate balance between strength and softness, that our journey through the world of custom apparel continues.

The Art of Screen Printing

What is Screen Printing?

Screen printing, a craft tracing its origins to ancient China, has evolved into a modern printing technique favored for its versatility and vibrant results. This method involves transferring ink through a mesh screen onto a substrate, with each color in a design requiring a separate screen. Its popularity is largely due to the durability of the prints and the ability to produce large quantities efficiently.

Different types of screen printing techniques

Multiple screen printing methods exist, each suited to different project needs. The most common include spot color screen printing, which uses individual colors for clarity and consistency, and CMYK or four-color process printing, which blends base colors for a photographic finish. Then there's discharge screen printing, which removes dye from fabric, leaving a soft-hand feel to the garment, and specialty inks, such as metallic or glow-in-the-dark, which add unique effects.

When to choose Screen Printing over other methods

Screen printing is the go-to for bulk orders, especially when dealing with designs that have limited colors. Its cost-effectiveness for large runs, coupled with the superior quality of vibrant and long-lasting prints, makes it a preferred choice for businesses and individuals alike. Moreover, screen printing on a variety of materials, ranging from textiles to metal and glass, offers a broad canvas for creativity.

Screen Printing Materials and Inks

The choice of inks and materials in screen printing is pivotal. Plastisol inks are renowned for their color vibrancy and durability, while water-based inks are celebrated for their eco-friendliness and soft-hand feel. The selection of the substrate is also crucial, with cotton being a favorite due to its absorbency and smooth surface, which ensures high-quality prints.

Best fabrics and materials for screen printing

Screen printing shines across various textiles, but natural fibers like cotton and silk hold ink best. Blends can also yield excellent results, though the choice of ink may vary depending on the fabric composition. The key is to match the material with the right type of ink to ensure the longevity and visual appeal of the print.

Longevity and care of screen-printed products

Screen-printed items, when properly cared for, can withstand numerous washes without fading. Turning garments inside out, washing them in cold water, and avoiding harsh detergents are some care tips that can help preserve the vibrant prints. It's also recommended to avoid direct ironing on the print to maintain its crispness.

Cost and Efficiency of Screen Printing

Screen printing is an economical choice for larger orders, as the cost per unit decreases with the number of garments produced. The initial setup cost is distributed over the quantity, making it less economical for smaller runs.

Production time for screen printing jobs

Screen printing requires meticulous setup, which can extend the production time, especially for complex, multi-color designs. However, once the setup is complete, printing is relatively quick, allowing for the efficient production of large batches, and making it an ideal choice for time-sensitive orders.

Scalability of screen printing for large operations

For businesses scaling up their production, screen printing offers an excellent advantage. The ability to print hundreds, if not thousands, of items in a single run makes it a scalable solution for growing operations. The process can easily be automated, further enhancing the capacity for larger print jobs.

As we wrap up our in-depth look at the nuances of screen printing, it's clear that this age-old technique has stood the test of time, adapting to the needs of modern apparel production. It's the perfect amalgamation of art and industry, resulting in wearable masterpieces that resonate with the ethos of streetwear and vintage fashion. As we transition to our next section, let's consider the intersection of quality and durability, where screen printing meets the contemporary demands of custom apparel—a narrative that continues to evolve as we push the boundaries of textile artistry.

DTG vs. Screen Printing: Which Wins on Quality & Cost?

The debate between Direct to Garment (DTG) and Screen Printing is a tale as old as modern custom apparel itself. Both methods offer unique benefits and drawbacks, and the choice between them often hinges on the specifics of your project. If you're seeking vivid detail and color accuracy, DTG might be your go-to, as it allows for a broader spectrum of colors and finer detail. On the other hand, Screen Printing stands out for its durability and cost-effectiveness in larger batches. But how do these methods stack up when it comes to quality and cost?

Comparison of Print Quality

When it comes to print quality, DTG printing shines with its ability to produce intricate designs with a vast range of colors. The technique operates much like a traditional inkjet printer, reproducing digital images directly onto the fabric. This means that even the most complicated graphics come out with a high level of clarity and precision. In contrast, Screen Printing utilizes stencils and ink which is passed through mesh screens, layer by layer. Although this method might not match the detail of DTG, it offers a unique texture and a classic look that's hard to replicate with digital methods.

The fabric choice significantly impacts the print quality. While DTG is versatile across different textiles, Screen Printing often requires a smooth, flat surface to ensure the ink adheres well and the design stays sharp. This might limit your fabric options but contributes to a more consistent and durable result.

Durability and Longevity of Prints

Durability is a critical factor when comparing DTG and Screen Printing. Screen Printing inks are known for their ability to withstand countless washes without fading, partly because the ink is absorbed deeply into the fabric. DTG prints, while vibrant at first, can begin to show wear after multiple washes. It's essential to follow care instructions to preserve the quality of DTG prints.

To maintain the integrity of either print type, it's advisable to wash the garments inside out, use cold water, and avoid harsh detergents. Such precautions help in extending the life of the print, ensuring that the colors stay true for as long as possible.

Real-world Applications and Use Cases

In the bustling city of Los Angeles, where V.S. Tees calls home, both DTG and Screen Printing have their place. Small businesses and startups might lean towards DTG for small-batch custom prints due to its lower upfront costs and flexibility with intricate designs. Conversely, Screen Printing remains the favorite for larger orders where uniformity and cost reduction are paramount. The music and entertainment industry often gravitates towards Screen Printing for merchandise due to its scalability and time-tested resilience.

Understanding the real-world applications and use cases of each printing method is essential for making an informed decision. DTG might be ideal for a one-off custom shirt for a birthday party, while Screen Printing would be the method of choice for outfitting an entire sports team with durable uniforms.

When considering the right printing method for your next project, it's not just about quality and cost, but also the application and purpose of the final product. As we pivot into examining the business perspective in choosing the right printing method, remember that your unique needs and preferences should guide your decision. Whether it's the bespoke touch of DTG or the enduring appeal of Screen Printing, V.S. Tees stands ready to deliver with expertise shaped by the vibrant and eclectic tapestry of Los Angeles streetwear culture.

The Business Perspective: Choosing the Right Print Method

In the world of fashion and custom apparel, the decision between DTG (direct-to-garment) and Screen Printing can significantly impact your brand's trajectory. Both methods offer unique advantages and considerations, especially when it comes to cost and quality, which are paramount for startups and SMEs (small and medium-sized enterprises).

Cost Implications for Startups and SMEs

When launching a clothing line or custom apparel business, it's crucial to weigh the initial investment of your printing setup. DTG printers, while offering a plethora of color options and intricate designs, come with a higher upfront cost. In contrast, screen printing requires less costly equipment but involves more labor, especially with multiple colors.

A break-even analysis is indispensable to understanding the financial landscape. It helps you quantify how many shirts you need to sell to cover your costs with either method. For DTG, although the cost per shirt is typically higher, the ability to print on demand without the need for setup means that you can start selling with minimal inventory. Screen printing, meanwhile, becomes cost-effective with larger orders, leveraging economies of scale.

Decision factors for startups are multifaceted. You must consider not just the financial outlay but also factors like design complexity, order size, and fabric compatibility. For instance, screen printing may be more suitable for simple designs in large quantities, while DTG excels with complex, multicolored images, especially for small batches.

Scaling Production with DTG or Screen Printing

As your business grows, so does the need to scale your production capacity. DTG printing allows for easy scalability with its print-on-demand model. You can increase output simply by adding more printers without a corresponding increase in labor. However, the per-unit cost remains relatively unchanged, and large orders can be time-consuming.

In contrast, screen printing's scalability is labor-intensive. Adding more machines often means hiring more staff to operate them. However, with increased production, the cost per unit can decrease, making screen printing an attractive option for expansion if you anticipate consistently high order volumes.

Strategic planning for growth with these print technologies involves a careful analysis of your projected sales, order sizes, and design requirements. Should your brand lean towards bespoke, limited-edition runs, DTG might be your ally. Conversely, if you're aiming for mass distribution of a few designs, screen printing could be your cornerstone.

Environmental and Sustainability Considerations

Today's consumers are increasingly concerned with environmental impact, and this extends to their clothing choices. DTG printing boasts eco-friendliness with its water-based inks and reduced waste. There's no need for screens or emulsions, which means fewer chemicals and less water usage. However, the energy consumption of DTG printers can be substantial.

Screen printing, while traditional, can pose environmental challenges. The inks used are often plastisol-based, which contain PVC and phthalates — not the most eco-friendly materials. Waste management becomes a critical issue, with the necessity to dispose of used screens and excess ink responsibly. However, advancements in biodegradable inks and more efficient processes are helping screen printing evolve toward sustainability.

Sustainable practices in the printing industry are not just about the materials used, but also the longevity of the product. A well-made screen-printed shirt can last for years, reducing the need for frequent replacements and, consequently, the environmental footprint. Similarly, the durability of DTG prints has improved, making them a viable option for those seeking sustainable solutions.

As we consider the future of apparel customization and production, it's essential to recognize the evolving landscape of technology and consumer preferences. Keeping abreast of new developments and adapting your business model to incorporate them can be the difference between thriving and merely surviving in this competitive market. Whether it's the latest in eco-friendly ink formulations or cutting-edge printing techniques, staying informed and flexible will serve your brand well.

For those eager to delve deeper into this comparison, informative resources are available that explore various aspects of DTG vs. Screen Printing, including detailed cost breakdowns, environmental considerations, and more.

Incorporating my own experiences, I've witnessed the appeal of streetwear fashion and vintage-inspired clothing first-hand. Our online store, V.S. Tees, speaks directly to this niche market, offering both premium blanks and custom printing services that resonate with the individuality and creativity our customers crave. With each unique design we produce, whether through DTG or screen printing, we reinforce our commitment to quality and the distinct style that streetwear enthusiasts admire.

Technological Advancements and Future Trends

The printing industry is at the cusp of a revolution, constantly evolving with innovations that redefine how we perceive print quality and efficiency. As we gaze into the horizon, it's evident that technological advancements are reshaping both Direct to Garment (DTG) and Screen Printing methodologies.

Innovations in DTG Printing

DTG printing has seen a surge in technological advancements. With state-of-the-art printers now equipped with precision nozzles and advanced ink technology, the level of detail achieved is staggering. The integration of AI has led to smarter color matching and image processing, allowing for prints that are not only vibrant but also incredibly accurate to the original design.

The emerging trends in DTG print applications are expanding the market's reach. From eco-friendly inks to 3D printing capabilities, the DTG industry is not just about putting a design on a tee; it's about creating a wearable piece of art. The future outlook for DTG printing is promising, with predictions pointing towards further automation, faster print times, and a broader spectrum of printable fabrics.

Evolution of Screen Printing Techniques

Technological improvements in Screen Printing are equally impressive. Automated presses and precision stenciling have significantly increased the throughput while maintaining, if not improving, the quality of prints. The introduction of new screen printing materials and methods—such as high-opacity inks and digital hybrid techniques—has expanded the creative possibilities for designers and printers alike.

The predictions for the future of Screen Printing focus on sustainability and efficiency. Innovations in ink formulations and energy-saving press designs are anticipated, which not only promise to reduce the environmental impact but also to lower production costs, making screen printing an even more attractive option for large runs.

DTG vs. Screen Printing: Looking Ahead

In the anticipated developments in print quality and efficiency, both DTG and Screen Printing are poised to offer more with less—less waste, less time, and less environmental impact. The potential shifts in industry preferences may lean towards DTG for its versatility in small runs and customization, while Screen Printing might continue to dominate in large-scale productions due to its cost-effectiveness.

As we prepare for future changes in the printing landscape, businesses and individuals in the industry need to stay updated with the latest techniques and embrace the innovations that will drive the market forward. Whether you're a designer, a printer, or a fashion enthusiast, understanding these trends will help you make informed decisions for your creative projects.

As we contemplate these advancements, it's clear that DTG and Screen Printing have their unique strengths and are likely to grow in parallel, catering to different needs within the diverse world of print apparel. If you're seeking to create a fashion statement with your next project, or perhaps considering a venture into the custom apparel business, the choice between DTG and Screen Printing will be pivotal. It's about aligning with your vision, whether it's the artisanal charm of Screen Printing or the cutting-edge precision of DTG that will bring your creative concepts to life.

Conclusion

When weighing the pros and cons of DTG vs. Screen Printing, it's clear that each method has its own set of advantages tailored to specific needs and goals. As we stand at the forefront of custom apparel at V.S. Tees, we understand that the choice between these two printing techniques can significantly impact the final product. Whether you're after the vibrant and precise details that DTG printing offers for small batch orders or the durability and cost-effectiveness of screen printing for larger volumes, we're here to guide you through the decision-making process.

Key Takeaway:

Your printing method should align with your vision for quality, the scale of production, and the intricate designs you wish to bring to life.

At VS Tees, our commitment to excellence ensures that whether you choose DTG or Screen Printing, your garments will capture the essence of your brand with impeccable quality. If you're ready to elevate your apparel with custom printing that speaks volumes, reach out to us through our contact form. Let's make your designs wearable art that stands out in the bustling streets of Los Angeles and beyond.