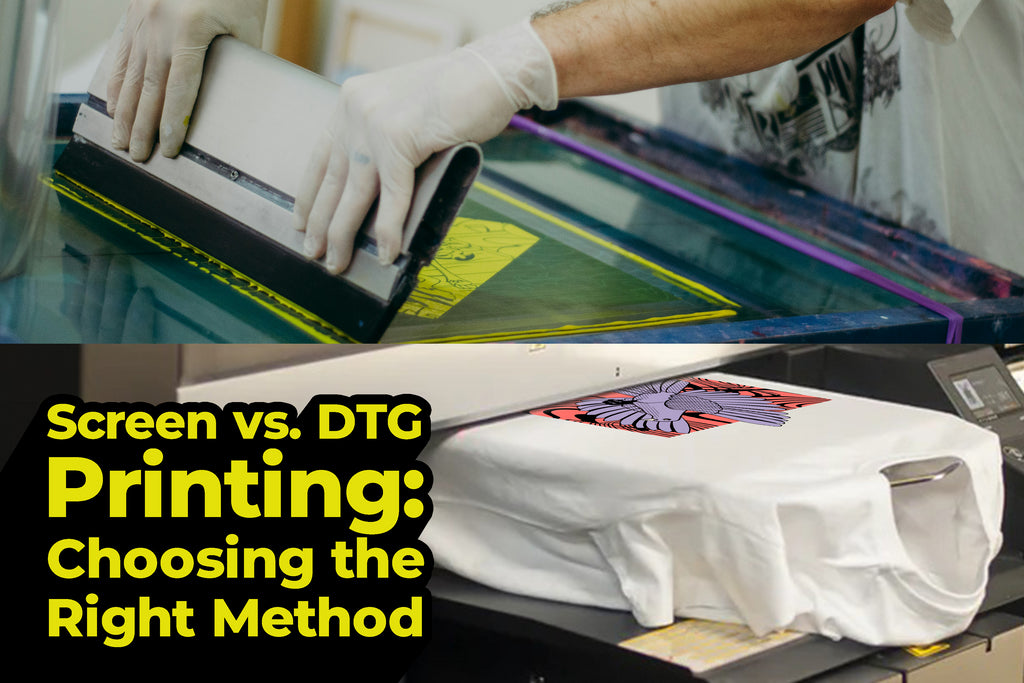

Screen vs. DTG Printing: Choosing the Right Method

Posted by ARTEMIO NERVEZ JR

In the world of custom t-shirt printing, two technologies dominate the landscape: traditional screen printing and the newer direct-to-garment (DTG) printing. We offer both options at VS Tees because we understand that different projects require different approaches. This guide will help you understand the key differences between these methods and determine which is right for your specific needs.

Understanding Screen Printing

Screen printing is a time-honored technique that has been the industry standard for decades. The process involves creating a stencil (called a screen) for each color in your design and pushing ink through these screens onto the fabric.

Advantages of Screen Printing

- Cost-effective for large orders: Once screens are created, each additional print adds minimal cost, making the per-unit price decrease significantly as quantities increase.

- Vibrant, durable results: Screen printing produces exceptionally vivid colors with excellent durability. The ink sits on top of the fabric, creating a distinct feel and impressive longevity even after numerous washes.

- Specialty ink options: Screen printing accommodates specialty inks such as high-density, puff, metallic, and glow-in-the-dark options that simply aren't possible with DTG.

- Works on various materials: Beyond cotton, screen printing performs well on polyester, blends, and even non-traditional surfaces like tote bags and koozies.

Limitations of Screen Printing

- Higher setup costs: Creating screens requires significant preparation, making small orders more expensive per unit.

- Color limitations: Each color requires a separate screen, which increases both cost and production time. Complex, multi-color designs can become prohibitively expensive.

- Less detail precision: While still capable of impressive results, screen printing cannot reproduce the photographic-level detail that DTG can achieve.

Understanding DTG Printing

Direct-to-garment printing is essentially a specialized inkjet printer for textiles. The technology has advanced significantly in recent years, making it an increasingly popular option.

Advantages of DTG Printing

- Perfect for complex designs: DTG excels at reproducing photographs, gradients, and complex graphics with virtually unlimited colors.

- Ideal for small orders: With minimal setup requirements, DTG is economical for small runs and even single items.

- Print-on-demand capability: The digital nature of DTG allows for efficient on-demand printing without inventory concerns.

- Soft hand feel: DTG ink absorbs into the fabric rather than sitting on top, resulting in a softer feel that some customers prefer.

Limitations of DTG Printing

- Higher per-unit cost for large orders: Without the economies of scale that screen printing offers, DTG typically maintains the same per-unit cost regardless of quantity.

- Color vibrancy challenges: While improving, DTG prints generally don't achieve the same level of vibrancy as screen printing, especially on colored garments.

- Primarily limited to cotton: DTG produces its best results on 100% cotton or high-cotton-content blends. Results on polyester can be disappointing.

- Less durable over time: DTG prints typically don't last as long as screen prints, sometimes fading more noticeably after repeated washing.

Making the Right Choice for Your Project

Choose Screen Printing When:

- Your order quantity exceeds 24 pieces

- Your design uses 1-4 solid colors without gradients or photographic elements

- Maximum durability is important

- You need specialty inks like metallic or puff

- You're printing on polyester or blended fabrics

- Brand consistency across items is crucial

Choose DTG Printing When:

- You need a small quantity (1-24 pieces)

- Your design features complex graphics, photographs, or numerous colors

- You want a soft, barely-there feel to the print

- You need quick turnaround time

- You're printing on 100% cotton garments

- You want to offer varied designs without inventory concerns

Hybrid Approaches

At VS Tees, we sometimes recommend combining both methods for certain projects. For example, screen printing a logo on the front of a shirt with DTG for complex designs on the back. This hybrid approach allows you to leverage the strengths of each method.

Conclusion

Both screen printing and DTG have their rightful place in the custom apparel world. By understanding the strengths and limitations of each method, you can make an informed decision that balances quality, cost, and suitability for your specific project requirements.

Ready to start your custom t-shirt project? Contact VS Tees today for a consultation on which printing method will best bring your vision to life.